Table of Contents

Upcoming Batches ofLean Six Sigma Black Belt Course:-

| Batch | Mode | Price | To Enrol |

|---|---|---|---|

| Starts Every Week | Live Virtual Classroom | 29500 | ENROLL NOW |

Six Sigma is a known Process Improvement Methodology which helps in minimizing defects & helps to achieve excellence. This blog mainly talks about how to achieve excellence in Six Sigma Black Belt.

What is Six Sigma?

What is DMAIC METHODOLOGY?

DAMIC is data-driven Problem Solving approach for achieving Process excellence, it has 5 phases

| Define | Define the Problem |

| Measure | Measure the Problem |

| Analyze | Identify the actual cause of the problem |

| Improve | Try to solve the exact route cause of the problem |

| Control | Maintain or control the |

DMAIC is a Process Improvement Methodology

Case study 1

Let’s take an example of a Recruitment firm, Recruiters often experienced interview no shows

All Team Members including Manager arrived at a conclusion that process followed could be the main reason for no shows

| Define | Candidates are not attending the interview as scheduled & experiencing No Shows, the candidate is not turning up for the interview |

| Measure | Data was noted down, Approximate how many interviews were scheduled that month & how many attended the interview |

| Analyze | Pointers were discussed and proper methodology was set for recruiters when they are scheduling the interviews questions like what could be the reason for a candidate to look for the job is noted, if shown interest follow up call was set by different team members just to check the pulse of the candidate whether he is interested in job change & if scheduled whether the candidate is attending the interview as scheduled in future if the candidate is little hesitant then they were dropped from the interview process |

| Improve | Relationship building exercises were conducted for all Recruiters & proper training was provided to best judge candidates interest, and appealing job description is prepared to attract job seeker to apply and show interest |

| Control | The standard template was prepared for recording why actually job seeker is looking for the job change and upon detailed evaluation, they were shared with interview call letters |

Since we have 2 types of job seekers a proper content should be presented to attract them to apply for all open positions & follow up periodically to interest check candidates mindset minimized the interview No Shows in the coming days.

Branding and offers were made mandatory to engage passive job seekers and more research was done to inculcate the modern recruitment methodologies.

The problem was identified measured, Analysed, Improvised & controlled thereafter to experience excellence in the hiring process.

For improvising and measuring the problem area lot of data is collected by holding discussions with subject matter experts and top executives.

“Define, measure, analyze, improve, and control (DMAIC) is a data-driven excellence strategy used to improvise processes in the problem area. … It is an essential part of Six Sigma resourcefulness, but in general, can be implemented as a separate quality improvement technique or as part of other process improvement strategies.”

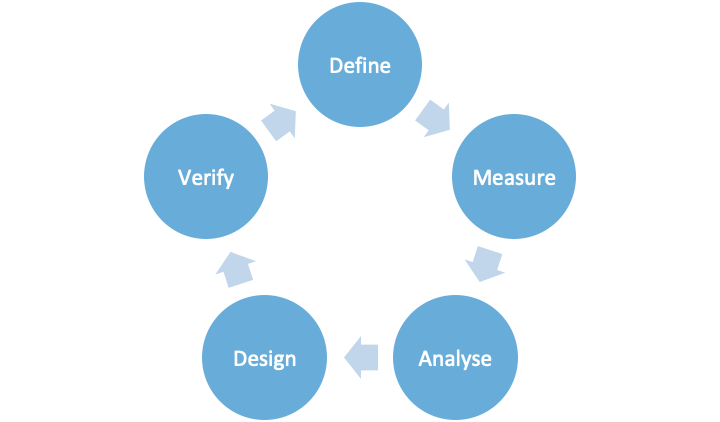

What is DMADV Process?

DMADV is again one more methodology to improve the new process

| Define | Define the problem area |

| Measure | Quantify the Problems |

| Analyze | Research to establish possible solutions |

| Design | Higher research to establish solution by exact wants/Needs pointers |

| Verify | Test and implement a methodology to see outcomes and finalize if everything is OK |

“The basic difference between DMAIC and DMADV frameworks is, DMAIC will be used when you are trying to improvise or progress a process which is already into presence. However, the DMADV (Define-Measure- Analyse-Design- Verify) method aims to redesign a challenging process or product”

Case Study 2

Let’s Apply DMADV methodology for a previous case study this time Problem area is Joining No Shows

| Define | Candidates are not joining the company after receiving the offer. |

| Measure | Data was noted down, possible means of delimiters which are stopping candidate to join after receiving the offer |

| Analyze | How effective ways can be adopted to attract talent till onboarding is discussed and certain ways are established by which Joining No Shows can be minimized. |

| Design | Studies and researches were conducted of other Organizations/competitors how they achieve a complete recruitment life cycle till onboarding. Addition of job roles and enriching existing role Providing extra monetary benefits and introduction of employee engagement policies that were broadcasted in social media and thus attracted passive candidates. |

| Measure | Parameters are set to evaluate the effectiveness of the implemented methodology. Periodic checks were conducted about the implemented strategies, changes were adopted wherever required if necessary and documented. |

Both these studies implemented DMAIC and DMADV methodology to improvise the process in the organization.

DMAIC and DMADV methodologies were used for new or existing process

[Must read: Top 20 Online Six Sigma Black Belt Certification ]

Six Sigma Tools

There are important tools used in Six Sigma Process Improvement

| 5 Why Analysis | To determine the root cause of the problem in DMAIC 5 why is used Upon getting Problem statement Example Not able to hire people for the company 1st Why: Is present Organization structure and brand values are obstacles for attracting talent? 2 Why: Is there any obstacle within the company culture? 3 Why: Is Hiring team is failing to reach candidates? 4 Why Is there any statutory barrier which is stopping the job aspirants to apply for your opportunities created? 5 Why Are Social media presence and rating by your ex-employees is creating a negative impact on job seekers? |

| 5 S Process | The detailed 5 S’s are given below: 1. Seiri (Sort) – Eliminate all unnecessary items for your current production, keeping only what is most necessary. 2. Seiton (Set In Order) – Consolidate the remaining items and label them accordingly. 3. Seiso (Shine) – Keep your work area clean and hygienic and organized, and examine your work area and everything in it every day. 4. Seiketsu (Standardize) – Write out your standards for the Sort, Set In Order, and Shine steps above. 5. Shitsuke (Sustain) – Apply the standards you’ve set for your establishment and make them habits for all employees in your organization. |

| Value Stream Mapping | Process of showing flow of materials and information in the organization, below are value stream mapping things Value enabling MethodsValue-adding Process/methodsNon-value adding methods |

| Regression Analysis | Graphical representation of Statistical process illustrating the relation between Variables |

| Pareto Chart | Graphical representation displaying the difference in groups of data |

| Failure Mode effective Analysis FMEA | Benefits businesses identify and eliminate feeble points in the early stages of any product or process. |

| Kaizen Continual improvement | Kaizen is a Japanese word meaning “change for the improved” or “continuous improvement.” Kaizen guarantees that waste will be progressively reduced through the collective faculties and knowledge of everyone in the company working together to change the smallest disorganizations daily. |

| Poka-yoke Mistake proofing | Japanese word meaning mistake proofing |

Different Six Sigma Roles

| Leadership Key Executives | CEO/MD/GM/VP or any key executives of the company |

| Champions | Implement Six Sigma in Organization & guide to black belts |

| Master Black belt | Selected by Champions and act as Subject Matter Experts |

| Black belts | Help MBB in applying Six Sigma Methodologies across and help the organization in improvising and eliminate defects |

| Green Belts | Employees who take up necessary training in Six Sigma & helps in Implementing Six Sigma Methodologies apart from their routine tasks, they operate under the guidance of black belts |

Deliverables of a Master Black Belt:

Six sigma key planning and roll-out plan in the organization/function/Process

Manage and control Project of the function

Guide Teams in knowledge transfer

Accomplish Lean Six Sigma Results

Cross-Functional expertise for leading projects effectively.

Project Implementation and Removing Obstructions

Deliverables of a Black Belt:

Six sigma key planning under the guidance of Master Black Belt and roll-out plan for the given process/zone/function

Execution of assigned Projects

Help and train Project Teams/Resources and Support in the removal of project-level Obstructions

Team and Project Structuring

Accomplish 6 sigma Project Results

Guide Green Belts in all project phases

{ Read more: Lean Six Sigma Black Belt Certification Training – Online Live Course | Henry Harvin® }

Deliverables of a Green Belt:

Project Execution as guided by a black belt, seeking Black belt support in execution activities.

Squad and Project Organising

Ensuring Six Sigma Project Results as guided by Black belts

Working with all designated team members in six sigma project

Below are some handpicked YouTube videos which you can watch and learn about the basics of Six Sigma

| Introduction to Six Sigma | https://www.youtube.com/watch?v=GiCMGL7RqRw |

| What is Six Sigma | https://www.youtube.com/watch?v=7_oWjQfQmZk |

| DMAIC Six Sigma Methodology | https://www.youtube.com/watch?v=Bh8Ke7hxJ1s |

| A Simple explanation of Six Sigma | https://www.youtube.com/watch?v=Kz_7njsDUMQ |

| Six Sigma Overview | https://www.youtube.com/watch?v=IHC6YNFQ38w |

| What is Six Sigma Step by Step explanation | https://www.youtube.com/watch?v=9gTQfAzxDq4 |

| What is Sigma explained with the case study | https://www.youtube.com/watch?v=86XJqf1IhQM |

| Six Sigma Belts Explained | https://www.youtube.com/watch?v=q2LZVfqj36g |

| Introduction to Six Sigma | https://www.youtube.com/watch?v=DxNicBRCPi4 |

| Six Sigma Explained | https://www.youtube.com/watch?v=-cDfML-UlSA |

Now, are you interested? To take learn Six Sigma & take up the role as Black Belt below are the insights for your aspirations

What are the necessary qualities for the Six Sigma Black Belt?

- Proven Leadership Style to lead Six Sigma Project Teams

- Zeal to complete assigned six sigma project according to guidelines laid by Master Black Belt

- Quest to learn and implement the acquired knowledge

- Excellent Team handling ability with a helpful approach

- Advocacy

- Strong communication skills to cascade project deliverables across six sigma project organization

Qualities of Six Sigma Black belt explained

Leadership Style requirement

When assigned certain Project Leadership portfolio leader should gain the confidence of six sigma team members and leaders with examples by providing them helping hand always

Should possess enthusiasm in completing tasks in the given time, Team handling ability comes with Subject knowledge if the leader has subject expertise he can guide the team in problem situations, should possess good customer handling skills and must possess command over communication since he needs to cascade information to the seniors and juniors for all six sigma project updates, the result-oriented approach helps in leading teams and able to achieve excellence in given project deadlines.

If you have above qualities what you are waiting for explore Six Sigma Black belt certification from below reputed institutes and start your career as Six Sigma Black belt

| Tuv Sud |

| Benchmark Six Sigma |

| KPMG |

| Henry Harvin |

| ASQ Training |

| QUI Global |

| Six Sigma Institute |

| BSI Group |

Useful Online Courses for acquiring Six Sigma Knowledge

| Free Lean Six Sigma Training | https://goleansixsigma.com/free-lean-six-sigma-training/ |

| Six Sigma for beginners from Udemy | https://www.udemy.com/course/six-sigma-for-beginners-a-brief-overview/ |

| Six Sigma Black Belt level Regression Analysis Udemy | https://www.udemy.com/course/six-sigma-black-belt-level-regression-analysis/ |

| Lean Six Sigma Primer | https://www.udemy.com/course/free-lean-six-sigma-primer/ |

How Black Belt reach Excellence in Six Sigma we will enunciate

Black Belt’s will be experts in Six Sigma since they complete certifications and inculcate necessary Six Sigma expertise to lead six sigma Project teams, they will learn Six Sigma tools, Soft wares like Minitab and possess excellent technical and interpersonal skills which are necessary for any Project Leader .being good communicator act as a facilitator in Six Sigma project organization ensuring a smooth completion of all project phases planned in result-oriented ways.

[ Note: 6 Best Institutes for Six Sigma Certification in India ]

Conclusion

By completing necessary training and certifications in Six Sigma you can participate in Six Sigma projects in the organization and help in process improvements by minimizing defects

Six Sigma Black Belt will lead and guide the Six Sigma Projects in an efficient manner

DMAIC and DMADV are used throughout the Six Sigma Process

Frequently Asked Questions

| What are different certifications in Six Sigma | Green belt, Black Belt |

| What is course and certification duration | Option 1: Classroom Training of 48 hrs duration Option 2: Live Online Training of 28 hrs duration |

| Can we take up Black belt directly without Green belt certification | Yes, but it is advised to undergo Green belt training to gain know-how about Six Sigma methods and tools. |

| Any Qualification is mandatory | No, Not any specific qualification is required, only passion for learning and contributing to the organization is required. |

| Can you suggest the best certification and training institute for Six Sigma | Henry Harvin |

Recommended Programs

Lean Six Sigma Green Belt

Certification Training

Ranked No.1 Six Sigma Certification in India | Aligned to IASSC Book of Knowledge | Combining Lean and DMAIC Methodology to Impart Key Skills | Gain Experience of 12+ Projects | Both Classroom and Live Online Options Available

Lean Six Sigma Black Belt

Certification Training

Ranked No.1 Six Sigma Black Belt Certification in India | 9361+ Participants Trained | Aligned to IASSC Book of Knowledge (BOK) | Gain Advanced Expertise Over Lean and Six Sigma Methodology| Gain Experience of 12+ Projects | Both Classroom and Live Online Options Available

Lean Six Sigma Master

Black Belt Certification

Step-in to a new designation of being Explicit Quality Professional | Get acknowledged as a Lean Six Sigma Evangelist | Connect to the rarest community of worldwide Black Belt specialists | Validate your professional skills in leading intricate projects | Execute Lean methodologies with perfection.

Explore Popular Category

.webp)