Table of Contents

In a business problems, each subject isn’t if obstacles will occur, but when. As a professional in a management position, it’s your job to extinguish all fires that arise within your department.

But the truly great leaders also understand that success is oftentimes won by eliminating problems before they happen. This is where a root cause analysis can prove invaluable.

Upcoming Batches of Six Sigma Green Belt Certificate :-

| Batch | Mode | Price | To Enrol |

|---|---|---|---|

| Starts Every Week | Live Virtual Classroom | 19500 | ENROLL NOW |

In this blog post, we’ll discuss what a root cause analysis is, and we’ll outline an easy five-step process you’ll use to conduct one effectively.

Then we’ll illustrate the whole concept with a real-life example. Sound good? Let’s get started!

Root Cause Analysis: Definition

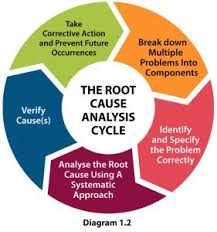

Let’s start with a definition root cause analysis, sometimes abbreviated to just Root Cause Analysis, which is a process used to determine the underlying cause of a problem.

When the underlying cause or root of an issue is identified and understood, it can be remedied and avoided in the future.

When a drag arises at work or in your personal life, having the ability to urge right down to the basis explanation for that problem will assist you to avoid making an equivalent mistake in the future.

Many organizations treat problem symptoms instead of root causes.

This is akin to weed whacking weeds in one’s garden. Yes, the current issue will be momentarily resolved.

But unless each weed is dug up and completely rooted out, the undesirable foliage will continue to sprout again and again.

- The key to discovering the root cause of a particular problem is to ask “why?”

- Why did that piece of equipment fail?

- Why did that employee make that decision?

And so on. Each “why” question should cause a further one until, eventually, a root cause is identified.

For Example

Let’s pretend that your wrists have been causing you great pain lately. So much so that you’ve requested time off from work to go see a doctor.

The physician informs you that you’ve developed carpal tunnel and writes you a prescription for medication.

The medication, while helpful, really only treats your current symptoms. If the root issue causing your wrists to hurt isn’t identified, the pain is likely to return in time.

You don’t want this to happen so you ask “why am I having this pain?” A thorough analysis reveals to you that the carpal tunnel was sparked by your voracious writing habit. You’ve been spending hours each night writing your debut novel.

All this time at the keyboard has caused your wrists to hurt, which caused you to miss work and visit your doctor, who prescribed medication. See how that works?

It should be noted that, while root cause analysis processes are generally wont to find and eliminate problems, this procedure also can be wont to identify success factors so that they can be repeated for continued success.

How to Perform a Root Cause Analysis

The simplest way to think about root cause analysis is to imagine a common problem you may experience in life, like if your home Internet suddenly stopped functioning.

If this occurred, you’ll drive to a cafe and use their Internet instead, but that solution wouldn’t only fail to require any corrective action but would also ignore the underlying causes of your problem.

A better solution would be to call your Internet provider and ask them to find the real cause of the problem.

What Is the Purpose of a Root Cause Analysis?

The primary purpose of the basis causes the analysis process is to research a drag or sequence of events to spot what happened, why it happened, and what can be done to prevent it from happening again.

3 Basic Types of Root Causes

Three basic types of root causes can have a potential impact on a problem:

Physical causes

A tangible item fails for whatever reason, e.g. if an MRI machine at a hospital stops working and prevents a patient from receiving the proper health care.

Human causes

Individual character or several organization members performed something incorrectly. Human error will often cause a physical cause, e.g. if a hospital’s quality management team didn’t perform an MRI machine’s scheduled inspection, which caused it to fail.

Organizational causes

When a system or process that an organization uses to do their jobs is faulty, e.g. if a hospital’s quality control department mistakenly thought it was the patient safety department’s responsibility to inspect the MRI machine and nobody corrected them.

THINK LIKE A PRO

Identify RCA in 5 Easy Steps

Let’s dig into a simple process for identifying root causes. Follow these five steps and you’ll be able to pinpoint not only what went wrong, but why, and use that understanding to ensure similar problems and mistakes are avoided in the future.

1. Realize the Problem

First, you need to identify what went wrong. What problem are you hoping to resolve by embarking on a root cause analysis process? Typically there are three basic kinds of problems:

Material-Based Problems

These problems occur when a specific material item has failed in some way, such as when a piece of machinery malfunctions.

People-Based Problems

A people-based problem occurs when human error is the cause of the current issue. Oftentimes nation problems will cause a cloth problem, e.g. a piece of machinery fails because an employee neglected to perform regular maintenance on it.

Organizational-Based Problems

An organizational problem stems from a company process or policy that causes an issue to occur. Keeping with our current example, maintenance on the malfunctioning piece of machinery occurred because the company process for assigning maintenance duties is faulty.

Decide which of these problems is to blame for the current issue and problem symptoms that you’re dealing with.

Also Check Our Other Courses:

- Six Sigma Green Belt Certification

- Six Sigma Black Bet Certification

- Six Sigma Master Black Belt Certification

2. Collect a Sufficient Amount of Data

Now that you know what the surface problem is and the symptoms that it’s causing, you need to collect as much data as possible.

Challenge yourself topics like, “How long has this problem existed in our company?” and, “What influence is it having on everyday processes?”

It’s beneficial to get a multitude of opinions at this stage. Ask your employees, the people who deal with this specific problem area regularly, for their input.

Their perspective will prove valuable as you work to identify and eliminate a problem’s root cause.

3. Identify the Associated Causal Factors

Now the analysis aspect of “root cause analysis” really enters the image fully force. Start this step by reconstructing a timeline of events.

What led to this current issue?

What other problems coexist with the current one you’re dealing with. Identifying a timeline and asking these kinds of questions will allow you to begin realizing specific causal factors.

A causal factor, as defined by TapRoot, is: “An action or lack of action that caused an Incident or made the incident worse.”

Causal factors are the reason you’re dealing with your current problem. And make no mistake, there are almost always multiple reasons. So dig deep when considering causal factors. Do your best to identify multiple ones, as long as multiples do exist. You’re much more likely to resolve issues this way.

4. Draw a Conclusion

At this point in your root cause analysis, you’ve clearly outlined the problem and identified the symptoms of it. You’ve also collected a sufficient amount of data, utilizing the knowledge and experience of your employees to do so, and drilled down to realize each causal factor.

Now it’s time to assemble all this information and draw a conclusion. Why did your problem occur?

You discover the answer to this question by taking each causal factor and asking “why?” until you find the root cause. Why did the machine malfunction?

Because Bob in the maintenance department didn’t perform routine maintenance. Why didn’t Bob perform his maintenance duties?

Because he got sick the day he was scheduled to. Why a different employee wasn’t assigned the work instead? Etcetera.

5. Implement Any Necessary Changes

Congratulations! At this point in the root cause analysis process, you’ve identified the real reason (or reasons) for the issue at hand. But your work isn’t quite done yet. You now need to develop and implement a practical solution to avoid this problem in the future.

What can you do to make sure this problem never happens again?

Do you need a new process?

How about a new piece of equipment or software?

Perhaps you need to hire an additional employee or two. Whatever solution you deem necessary, implement it right away! Waiting only opens the door to further complications.

Core principles of RCA

Several core principles guide powerful root cause investigation, some of which should now be visible. Not only will these help the analysis quality, but these will also help the analyst gain trust and buy-in from stakeholders, clients, or patients.

- Concentrate on improving and correcting root causes preferably than just symptoms.

- Don’t ignore the importance of treating symptoms for short term relief.

- Understand there can be, and often are, various root matters.

- Focus on HOW and WHY something happened, not WHO was responsible.

- Be systematic and get detailed cause-effect proof to back up root cause requirements.

- Provide enough information to inform a corrective course of action.

- Analyze how a root problem can be checked (or replicated) in the future.

As evidence of the above law: when we analyze deep issues and causes, it’s important to take a comprehensive and holistic approach. In addition to discovering the root cause, we should strive to provide context and information that will result in an action or a decision. Remember: good analysis is an actionable analysis.

Root Cause Analysis or RCA?

Root Cause Analysis or RCA is a very popular and frequently used technique to help people find the answer as to why a problem happened in the first place. Its objective is to identify the origin of a problem using a specific set of steps, with associated tools, to find the primary cause of the problem, so that you can:

Determine what happened

Determine why it happened

Figure out what to do to decrease the possibility that it will happen again

Root Cause Analysis assumes that systems and events are interlinked. An action in one area triggers an action in another and another and so on. By backtracking these actions, you can discover where the origin of the problem and how it grew into the symptom you’re now facing.

RCA looks at all the three types of causes. It involves scrutinizing the patterns of negative effects, finding hidden flaws in the system and discovering specific actions that contributed to the problem. This often means that RCA reveals more than one root cause.

Failure Mode and Effects Analysis (FMEA)

It is very important to thoroughly analyse the cause-and-effect process and find out the changes needed for the different systems. It’s also important to plan ahead to predict the effects of your solution. This way, we can identify the potential failures before they happen.

One way of predicting potential failures is to use Failure Mode and Effects Analysis (FMEA). This tool builds on the idea of risk analysis to identify points where a solution could fail. FMEA is also a great system to implement across your organization; the more systems and processes that use FMEA at the start, the less likely you are to have problems that need Root Cause Analysis in the future.

Impact Analysis is another useful tool here. This helps you explore possible positive and negative consequences of a change on different parts of a system or organization.

Another great strategy to adopt is Kaizen, or continuous improvement. This is the idea that continual small changes create better systems overall. Kaizen also emphasizes that the people closest to a process should identify places for improvement. Again, with Kaizen alive and well in your company, the root causes of problems can be identified and resolved quickly and effectively.

Does Root Cause Analysis Work?

For each company, and for each situation, different tools and processes will yield information about Root Causes. At Boeing, Root Cause Analysis of problems with the C17 aircraft finally yielded the Integrated Safety Management System, which has 12 essential elements, including open communication processes and challenging goals and objectives. Here’s how the process is described in an article called “Incredible Journey”:

Cause and Effect Analysis

This “mind-mapping” technique uses a fishbone diagram, brainstorming, and analysis to determine the cause that underlies a problem or issue within an organization. Together, a group determines the issues, the possible causes of the problem, and then the possible reasons behind the causes. Once a map is created, the group can analyse the results, determine the most likely causes, and begin developing ideas for addresses these root causes.

Pareto Analysis

According to the theory behind Pareto Analysis, 20% of causes lead to 80% of results. This goes for negative results as well as positive results. By analysing and scoring the negative outcomes of various causes, it’s possible to pinpoint the rotten 20%—and then target those causes for positive action. In other words, Pareto Analysis allows you to decide which problems really matter, and take action to eliminate them.

Cause and effect Fishbone diagram

A different standard method is building a Fishbone diagram, also called an Ishikawa diagram, to visually map cause and effect. This can help identify possible causes for a problem by encouraging us to follow categorical branched paths to potential causes until we end up at the right one. It’s similar to the 5 Whys but much more visual.

Typically we start with the problem in the middle of the diagram (the spine of the fish skeleton), then brainstorm several categories of causes, which are then placed in off-shooting branches from the most line (the rib bones of the fish skeleton). Sections are quite extensive and might involve things like “People” or “Environment.” After grouping the categories, we break those down into smaller parts. For example, under “People” we’d consider potential root cause factors like “leadership,” “staffing,” or “training.”

As we dig deeper into potential causes and sub-causes, questioning each branch, we meet up with the sources of the difficulty. We can use this method to eliminate unrelated categories and identify correlated factors and certain root causes. For uniformity, carefully consider the categories before creating a diagram.

Common categories to consider in a Fishbone diagram:

- Machine (equipment, technology)

- Method (process)

- Material (includes raw material, consumables, and information)

- Man/mind power (physical or knowledge work)

- Measurement (inspection)

- Mission (purpose, expectation)

- Management/money power (leadership)

- Maintenance

- Product (or service)

- Price

- Promotion (marketing)

- Process (systems)

- People (personnel)

- Physical evidence

- Performance

- Surroundings (place, environment)

- Suppliers

- Skills

If Root Cause Analysis can work for Boeing, chances are it can work for your company. The key is to start with the right questions, select the right tools, and follow up to ensure that analysis leads to action—and not to a dead end.

By using tools like Cause and Effect Analysis, Pareto Analysis, and the Five Whys, companies around the world are rooting out serious problems and planning for success. In this series on Root Cause Analysis, we dig deeper into each of these strategies, giving your team the problem solving tools it needs.

Tips for performing effective root cause analysis

Ask questions to clarify information and bring us closer to answers. The more we will drill down and interrogate every potential cause, the more likely we are to seek out a root cause. Once we believe we have identified the root cause of the problem (and not just another symptom), we can ask even more questions: Why are we certain this is the root cause instead of that? How can we fix this root cause to stop the difficulty from happening again?

Use simple questions like “why?” “How?” and “so what does that mean here?” to carve a path towards understanding.

Work with a team and get fresh eyes.

Whether it’s just a partner or a whole team of colleagues, any extra eyes will help us figure out solutions faster and also serve as a check against bias. Getting input from others will also offer additional points of view, helping us to challenge our assumptions.

Plan for future RCA

As we perform a root cause analysis, it’s important to remember the method itself. Take notes. Ask questions about the analysis process itself. Find out if a particular technique or method works best for your specific business needs and environments.

Learn to conduct root cause analysis for successes too

Root cause analysis may be a useful gizmo for deciding where something went wrong. We typically use Root Cause Analysis as how to diagnose problems but it is often equally as effective to seek out the basis explanation for a hit. If we find the cause of success or over achievement or early deadline, it’s rarely a bad idea to find out the root cause of why things are going well. This kind of analysis can help prioritize and pre-emptively protect key factors and we might be able to translate success in one area of business to success in another area.

Root Cause Analysis Resources

You can also search articles, case studies, and publications for Root Cause Analysis resources.

Books

The ASQ Pocket Guide to Root Cause Analysis

Root Cause Analysis: The Core of Problem Solving and Corrective Action

Root Cause Analysis: Simplified Tools and Techniques

The Root Cause Analysis Handbook

Data Quality: Dimensions, Measurement, Strategy, Management, and Governance

Case Studies

The Impact Of Human Factors On Lead Time (Journal for Quality and Participation) EDR, a provider of property management software solutions, applies the DMAIC process to uncover and address the root causes of a customer lead time problem.

Wind Power Company Gets to the Root of an Icy Issue (PDF)By identifying the root causes of turbine failure during inclement weather, Clipper Windpower increased customer satisfaction through improved turbine availability and saved $1 million in lost revenue.

R. L. Polk & Co.: Making Every Issue the Only Issue (PDF) Annual customer surveys for R. L. Polk & Co. identified opportunities for improvement in customer contact and issue resolution. By following the same steps for every issue and performing full root cause analysis for 100 percent of issues, Polk increased operational excellence and improved customer satisfaction.

Articles

The Art of Root Cause Analysis (Quality Progress) Five whys analysis is the art of systematically drilling down to a real root cause. Essentially, you can find the root cause of a problem and show the relationship of causes by repeatedly asking the question, “Why?”

Under Scrutiny (Quality Progress) A new definition of root cause could help people realize a systematic process beyond cause and effect is needed for root cause analysis.

Root Cause Analysis for Beginners (Quality Progress) An introduction to RCA, this article provides definitions, the four major steps of RCA, and an example problem and root cause summary table.

Digging For the Root Cause (Six Sigma Forum Magazine) At the philosophical level, there is no absolute root cause in the infinite chain of causation. With this concept in mind, the challenge is to know when to stop drilling down and conclude the root cause has been reached. In Six Sigma training there are three keys that can help achieve that end, which this article explores.

Webcasts

Root Cause Analysis for Beginners, Part 1

Root Cause Analysis for Beginners, Part 2

Solution Analysis – Root Cause Analysis

Certification

Manager of Quality/Organizational Excellence – CMQ/OE

Six Sigma Green Belt – CSSGB

Six Sigma Black Belt – CSSBB

Quality Process Analyst – CQPA

Quality Improvement Associate – CQIA

Courses

eRCA™ Fundamentals (Root Cause Analysis)

Root Cause Analysis

Root Cause Analysis: Solve Problems by Eliminating Causes

Key Points

Root Cause Analysis is a useful process for understanding and solving a problem.

Figure out what negative events are occurring. Then, look at the complex systems around those problems, and identify key points of failure. Finally, determine solutions to address those key points, or root causes.

You can use many tools to support your RCA process. Cause and Effect Diagrams and 5 Whys are integral to the process itself, while FMEA and Kaizen help minimize the need for RCA in the future.

As an analytical tool, RCA is an essential way to perform a comprehensive, system-wide review of significant problems as well as the events and factors leading to them.

Click on the button below to download a template that will help you log problems, likely root causes and potential solutions. Thanks to Club member weeze for providing the basis for this.

Recommended Reads

- Best Six Sigma Course in India

- Best Six Sigma Courses in Bangalore

- Best Six Sigma Black Belt Courses in Delhi

- Best Six Sigma Courses in Chennai

Recommended Programs

Lean Six Sigma Green Belt

Certification Training

Ranked No.1 Six Sigma Certification in India | Aligned to IASSC Book of Knowledge | Combining Lean and DMAIC Methodology to Impart Key Skills | Gain Experience of 12+ Projects | Both Classroom and Live Online Options Available

Lean Six Sigma Black Belt

Certification Training

Ranked No.1 Six Sigma Black Belt Certification in India | 9361+ Participants Trained | Aligned to IASSC Book of Knowledge (BOK) | Gain Advanced Expertise Over Lean and Six Sigma Methodology| Gain Experience of 12+ Projects | Both Classroom and Live Online Options Available

Lean Six Sigma Master

Black Belt Certification

Step-in to a new designation of being Explicit Quality Professional | Get acknowledged as a Lean Six Sigma Evangelist | Connect to the rarest community of worldwide Black Belt specialists | Validate your professional skills in leading intricate projects | Execute Lean methodologies with perfection.

Explore Popular Category

.webp)